E-bikes have become increasingly popular as a sustainable and efficient mode of transportation. With their ability to assist riders in pedaling, they are revolutionizing the way we commute. But have you ever wondered what types of e-bike motors are available? From hub motors to mid-drive motors, each has its own unique features and benefits. This article will explore the various types of e-bike motors, giving you a comprehensive understanding of the technology behind these incredible machines. So, whether you’re a beginner or a seasoned cyclist, get ready to embark on an electrifying journey as we uncover the world of e-bike motors.

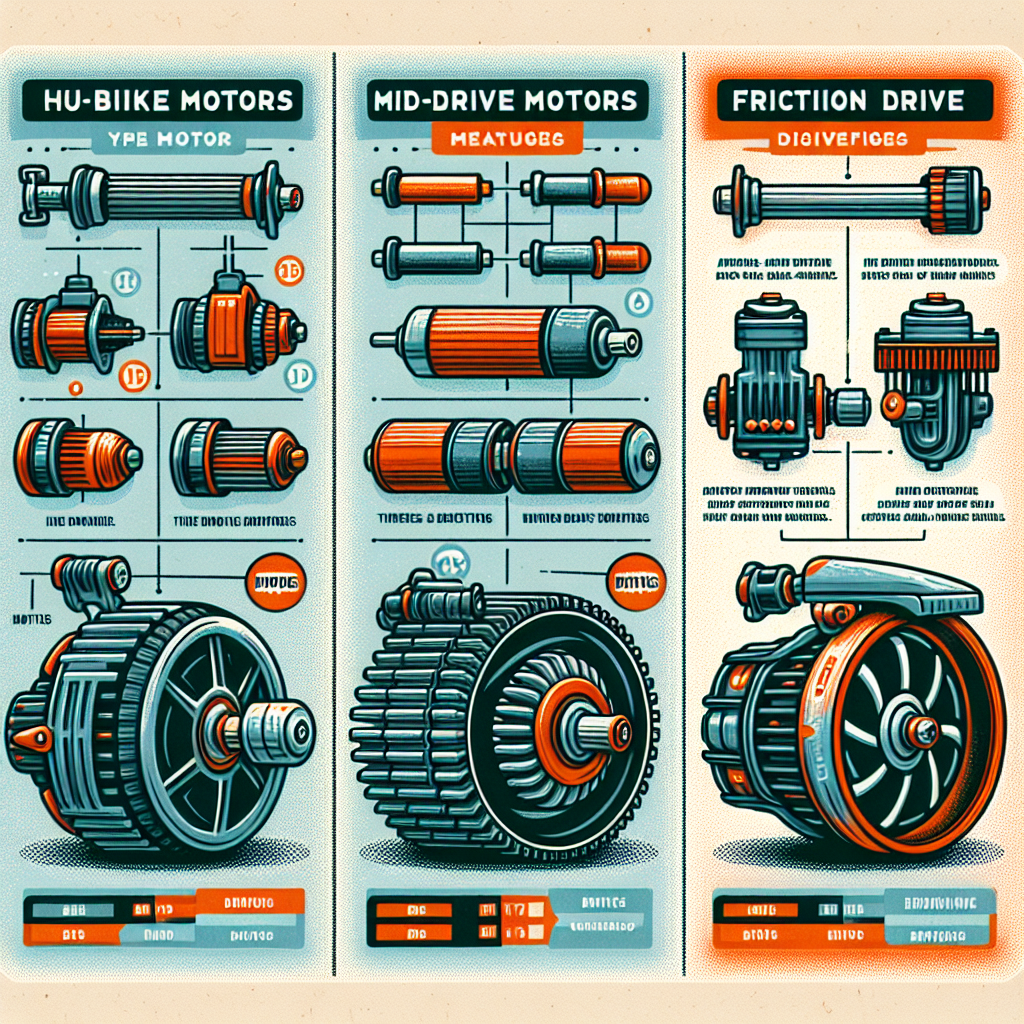

Hub motors

Direct-Drive Hub Motors

Direct-drive hub motors are a popular choice for electric bikes due to their simplicity and reliability. These motors are built directly into the hub of the wheel, eliminating the need for any additional drivetrain components. This makes them easy to install and maintain. Direct-drive hub motors also provide a smooth and quiet ride thanks to the absence of any gears or chains.

Geared Hub Motors

Geared hub motors, on the other hand, have a set of reduction gears built into the hub. These gears allow the motor to spin at a faster rate than the wheel, providing more torque for better hill-climbing ability and acceleration. Geared hub motors are generally lighter and more efficient compared to direct-drive hub motors. They are also smaller in size, making them a popular choice for compact electric bikes.

Mid-Drive Hub Motors

Mid-drive hub motors are mounted in the center of the bike frame, typically near the pedals. These motors transfer power to the drivetrain through the bike’s existing gears, providing a more natural and efficient riding experience. By utilizing the gears, mid-drive hub motors can take advantage of the bike’s full range of gears, making them suitable for different terrains and riding conditions. They also provide better weight distribution, resulting in improved handling and balance.

Mid-drive motors

Benefits of Mid-Drive Motors

Mid-drive motors offer several advantages over other types of e-bike motors. One of the biggest benefits is their ability to leverage the bike’s gears, allowing for improved efficiency, range, and climbing abilities. The weight distribution of mid-drive motors also enhances the overall balance and handling of the bike. Additionally, mid-drive motors provide a more natural riding experience, as the motor’s power is directly transmitted to the drivetrain, mimicking the feeling of pedaling on a traditional bike.

How Mid-Drive Motors Work

Mid-drive motors are designed to work in conjunction with the bike’s existing gears. When the rider applies pressure to the pedals, the motor engages and starts providing assistance. The power generated by the motor is then transferred to the drivetrain through the chain and gears, propelling the bike forward. This design allows for efficient energy utilization and provides the rider with a dynamic and versatile riding experience, suitable for various terrains and riding styles.

Direct-drive hub motors

Advantages of Direct-Drive Hub Motors

Direct-drive hub motors have several advantages that make them a popular choice among e-bike enthusiasts. One of the significant advantages is their simplicity. With no gears or complex moving parts, direct-drive hub motors are easy to install and maintain. They also provide a smooth and quiet ride, as there are no internal gears generating additional noise. Additionally, direct-drive hub motors offer regenerative braking capabilities, allowing the motor to recharge the battery during braking, enhancing the overall efficiency of the e-bike.

Disadvantages of Direct-Drive Hub Motors

Despite their many advantages, direct-drive hub motors also have a few disadvantages to consider. The primary drawback is their weight. These motors tend to be heavier due to the absence of gears and the need for more significant magnets and coils to generate the necessary power. This extra weight can impact the overall handling and maneuverability of the bike. Direct-drive hub motors also have a lower torque output compared to geared hub motors, which may result in slower acceleration and reduced climbing ability.

Geared hub motors

Advantages of Geared Hub Motors

Geared hub motors offer several advantages that make them a popular choice for electric bike conversions. One of the significant advantages is their compact size and lightweight design. The built-in reduction gears allow these motors to spin at a faster rate, providing more torque for better acceleration and hill-climbing abilities. Geared hub motors also tend to be more efficient, allowing for longer battery life and increased range. Furthermore, these motors are highly customizable, with the ability to choose gear ratios that suit specific riding needs.

Disadvantages of Geared Hub Motors

While geared hub motors have numerous advantages, they also come with a few disadvantages. One notable drawback is their higher maintenance requirements compared to direct-drive hub motors. The reduction gears in these motors are subjected to higher levels of stress and wear, requiring more frequent lubrication and potential replacement. Geared hub motors may also generate more noise compared to direct-drive hub motors, mainly due to the internal gears. Lastly, the added weight of the gears can impact the overall weight distribution and handling of the bike.

Mid-drive hub motors

Advantages of Mid-Drive Hub Motors

Mid-drive hub motors combine the advantages of mid-drive motors and hub motors, resulting in a versatile and powerful propulsion system for electric bikes. One of the significant advantages of mid-drive hub motors is their ability to leverage the bike’s gears, allowing for better efficiency and performance. The positioning of the motor in the center of the frame also provides improved weight distribution, enhancing the overall balance and handling of the bike. Additionally, mid-drive hub motors offer a more natural and responsive riding experience, as the motor’s power is directly transmitted to the drivetrain.

Disadvantages of Mid-Drive Hub Motors

Despite their many advantages, mid-drive hub motors also have a few disadvantages to consider. The added complexity of the drivetrain can lead to higher maintenance requirements compared to direct-drive and geared hub motors. The combination of gears and mid-drive motor can generate some noise during operation. Additionally, mid-drive hub motors tend to be more expensive due to the additional components and engineering required. However, for riders seeking the benefits of both mid-drive and hub motors, the advantages often outweigh these drawbacks.

Rear hub motors

Benefits of Rear Hub Motors

Rear hub motors offer several benefits that make them a popular choice for e-bike conversions. One of the significant advantages is their ability to provide a balanced and stable ride. The weight distribution of the motor in the rear wheel helps maintain traction and stability, particularly when climbing steep hills or navigating tricky terrain. Rear hub motors also tend to deliver more torque, making them suitable for riders who prioritize power and speed. Additionally, the position of the motor at the rear offers convenience for maintenance and rear wheel replacement.

Challenges of Rear Hub Motors

While rear hub motors have numerous benefits, they also come with a few challenges. One of the primary challenges is the added weight at the rear of the bike, which can impact the overall handling and maneuverability, particularly at higher speeds. Another challenge is the potential for increased stress on the rear wheel and frame due to the additional weight and torque generated by the motor. Riders should ensure that their e-bike frames and wheels are designed to handle the demands of a rear hub motor.

Suitable Applications for Rear Hub Motors

Rear hub motors are well-suited for applications where power and stability are essential. They are often preferred for off-road and mountain biking adventures, where the extra torque and traction can make a significant difference. Rear hub motors are also suitable for commuters who require a reliable and efficient mode of transportation. Additionally, riders with physical limitations or those seeking assistance on challenging terrains can benefit from the power and stability provided by rear hub motors.

Front hub motors

Benefits of Front Hub Motors

Front hub motors offer unique advantages that make them a compelling choice for certain riding scenarios. One significant benefit is the additional weight distribution at the front of the bike, which can improve traction and handling, particularly when riding on slippery or loose surfaces. Front hub motors also provide a more balanced and centered riding experience, making them suitable for riders who prioritize stability. Additionally, front hub motors offer ease of installation and maintenance, as they do not interfere with the drivetrain components.

Challenges of Front Hub Motors

Despite their benefits, front hub motors pose a few challenges that riders should consider. One notable challenge is the potential for reduced traction and steering control, particularly when accelerating or climbing steep hills. The weight distribution can lead to a lighter front end and affect stability during these maneuvers. Additionally, front hub motors may require a torque arm or additional reinforcement to handle the forces experienced during operation. The overall weight distribution should also be carefully considered to ensure the bike’s balance and handling remain optimal.

Suitable Applications for Front Hub Motors

Front hub motors are suitable for specific riding applications where enhanced traction and stability are paramount. They are particularly favored by riders who frequently encounter slippery or loose terrains, such as sand or snow. Front hub motors are often preferred for city commuting, providing a reliable and efficient means of transportation. Riders who prefer a more centered and balanced riding experience may also opt for a front hub motor. Additionally, front hub motors can be an ideal choice for e-bike conversions due to their ease of installation and minimal interference with the existing drivetrain.

All-wheel drive systems

Benefits of All-Wheel Drive Systems

All-wheel drive systems, also known as dual motor systems, offer a range of benefits that make them suitable for certain riding scenarios. One of the significant advantages is the increased traction and stability provided by the simultaneous power delivery to both the front and rear wheels. This enhanced traction is particularly valuable when riding on difficult terrains or in adverse weather conditions. All-wheel drive systems also offer superior power and acceleration, making them suitable for riders who prioritize speed and performance.

Challenges of All-Wheel Drive Systems

Despite their benefits, all-wheel drive systems come with a few challenges. One notable challenge is the increased complexity and weight of the installation. The presence of two motors, along with the associated wiring and control systems, adds additional components and weight to the e-bike. This increased weight can impact the overall handling and maneuverability of the bike. Additionally, the extra power generated by the dual motors may result in increased battery consumption, reducing the overall range of the e-bike.

Suitable Applications for All-Wheel Drive Systems

All-wheel drive systems are ideal for riders who require maximum traction, stability, and performance. They are often favored by off-road or mountain bike enthusiasts, allowing them to conquer challenging terrains with confidence. All-wheel drive systems can provide an extra boost of power for riders who enjoy the thrill of high-speed mountain descents or for those who frequently encounter steep inclines. Additionally, riders who live in areas with unpredictable weather conditions may find the enhanced traction of all-wheel drive systems advantageous.

Sensored motors

Working Principle of Sensored Motors

Sensored motors, as the name suggests, utilize sensors to provide precise control and feedback. These motors typically have sensors embedded in the motor’s windings or near the magnets. The sensors detect the position and speed of the motor’s rotor and provide real-time data to the motor controller. This information allows the controller to optimize power delivery, resulting in more efficient and responsive performance. The use of sensors also enables smoother and more accurate starting and stopping of the motor.

Advantages of Sensored Motors

Sensored motors offer several advantages that make them a popular choice for electric bikes. One significant advantage is the improved torque output and efficiency, particularly at low speeds. The sensors provide the motor controller with accurate information about the rotor position, allowing for precise timing of the power delivery. This results in enhanced torque and smoother acceleration, making sensored motors suitable for start-stop city commuting or navigating challenging terrains. Additionally, the use of sensors helps protect the motor from potential damage in case of overloading or overheating.

Disadvantages of Sensored Motors

While sensored motors have numerous advantages, they also come with a few disadvantages. One notable drawback is the added complexity and cost associated with the sensors and their integration with the motor controller. The presence of additional components increases the overall manufacturing and maintenance costs. Additionally, sensored motors may require careful calibration and tuning to ensure optimal performance, which can be time-consuming. Riders should also be aware that the sensors may be susceptible to damage from water or debris, requiring proper protection and maintenance.

Sensorless motors

Working Principle of Sensorless Motors

Sensorless motors, as the name suggests, do not rely on sensors to provide feedback to the motor controller. These motors utilize advanced algorithms and software to estimate the position and speed of the rotor based on other available data. This information is then used by the motor controller to deliver the appropriate power to the motor. Sensorless motors typically rely on the back electromotive force (EMF) or other electrical signals to determine the rotor position and adjust the power delivery accordingly.

Advantages of Sensorless Motors

Sensorless motors offer several advantages that make them a popular choice for electric bikes. One significant advantage is their simplicity and lower cost compared to sensored motors. The absence of sensors reduces the complexity of the motor and eliminates the need for additional wiring and control systems. Sensorless motors also tend to be more robust and resistant to water and debris, as there are no exposed sensors that could be damaged. Additionally, the lack of sensors allows for easier installation and reduced maintenance requirements.

Disadvantages of Sensorless Motors

Despite their benefits, sensorless motors also have a few disadvantages to consider. One notable drawback is the reduced efficiency and performance at low speeds. Without precise position feedback, sensorless motors may exhibit less torque and responsiveness during slow starts or steep climbs. Additionally, sensorless motors may be more prone to motor detection issues and require a specific speed threshold to start operating. Riders should also be aware that sensorless motors may generate more noise and vibration compared to their sensored counterparts.

In conclusion, e-bike motors come in various types, each with its own set of advantages and disadvantages. Whether it’s the simplicity and reliability of direct-drive hub motors, the efficiency and versatility of mid-drive hub motors, or the power and compactness of geared hub motors, riders have numerous options to choose from based on their specific needs and preferences. Additionally, the choice between sensored and sensorless motors allows riders to prioritize factors such as torque, efficiency, cost, and ease of maintenance. Consideration of these factors and understanding the characteristics of different e-bike motors can help riders make an informed decision when selecting the most suitable propulsion system for their electric bikes.