In today’s eco-conscious world, many people are opting for e-bikes as an environmentally friendly alternative to traditional bikes or cars. However, as the popularity of e-bikes continues to rise, questions arise about their impact on the environment, particularly when it comes to the disposal of their batteries. Can e-bike batteries be recycled? This article aims to shed light on the recyclability of e-bike batteries and explore the potential solutions for a greener future.

Overview of E-bike Batteries

E-bike batteries are an essential component of electric bicycles, providing the power necessary to propel the bike forward. These batteries are specifically designed to be lightweight, compact, and long-lasting, making them ideal for electric bikes. There are several different types of e-bike batteries available on the market, each with its own advantages and limitations. Understanding the composition and lifespan of these batteries is crucial for making informed choices about their use and recycling.

Types of E-bike Batteries

The most common types of e-bike batteries include lithium-ion (Li-ion), nickel-cadmium (Ni-Cd), and nickel-metal hydride (NiMH). Li-ion batteries are the most popular choice due to their high energy density, long lifespan, and lightweight design. Ni-Cd batteries, although less common, are known for their durability and ability to withstand extreme temperatures. NiMH batteries offer a good balance between energy density and cost-effectiveness. Each type of battery comes with its own set of advantages and considerations, making it important to choose the one that best suits your needs.

Composition of E-bike Batteries

E-bike batteries are typically composed of various components, including a cathode, an anode, a separator, and an electrolyte. The cathode and anode are made of different materials depending on the type of battery. For example, Li-ion batteries often use lithium cobalt oxide (LCO) as the cathode material and graphite as the anode material. The separator serves to prevent short circuits between the cathode and anode, while the electrolyte facilitates the movement of ions within the battery. Understanding the composition of e-bike batteries is essential for effective recycling and resource recovery.

Lifespan of E-bike Batteries

The lifespan of an e-bike battery depends on various factors, including the type of battery, usage patterns, and maintenance practices. On average, a well-maintained e-bike battery can last between 3 to 5 years, or even longer in some cases. However, over time, the battery’s capacity to hold a charge may decrease, resulting in reduced range and performance. It is important to remember that the lifespan of an e-bike battery can be extended through proper care and maintenance, such as avoiding extreme temperatures and ensuring regular charging.

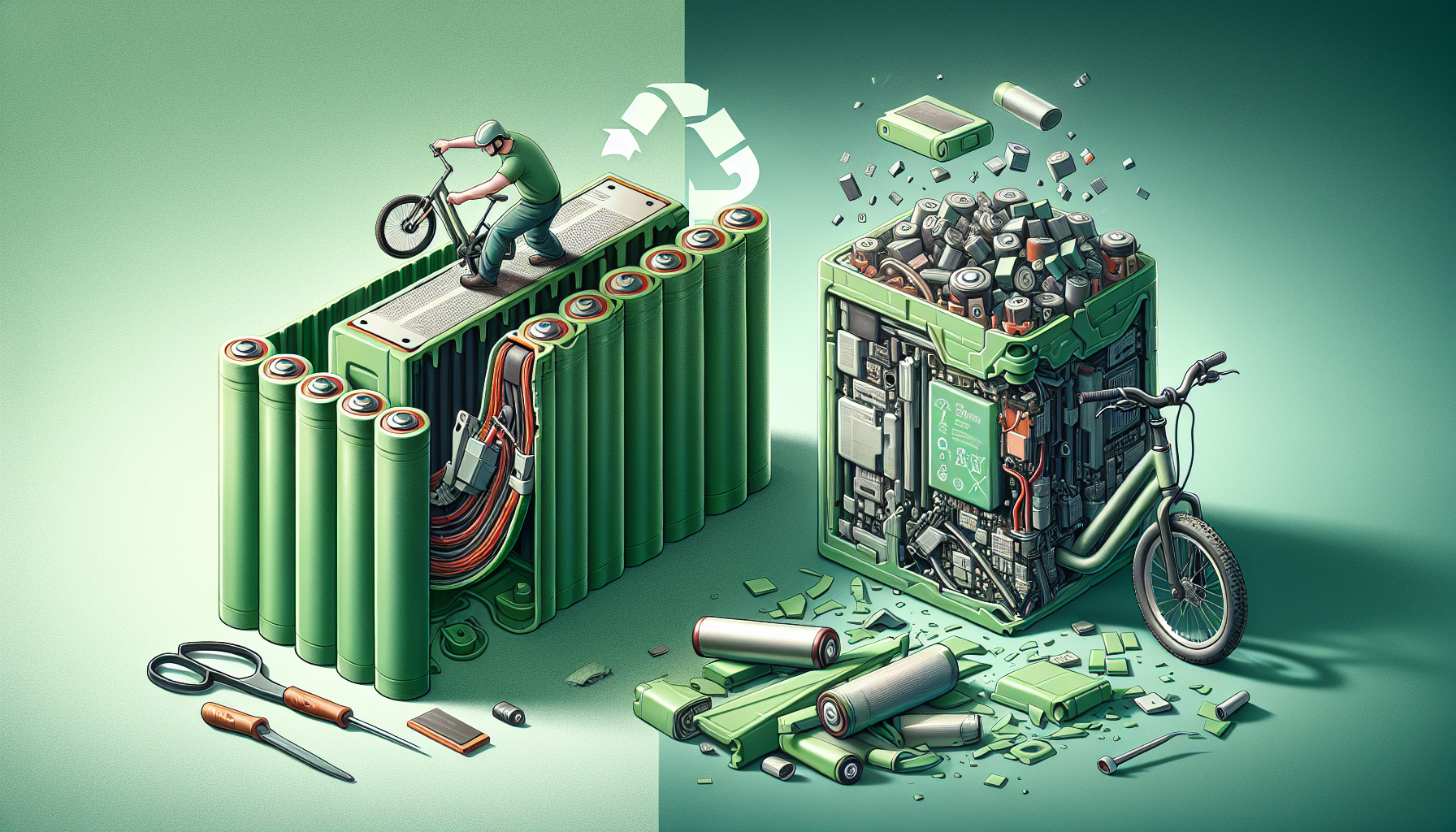

Importance of E-bike Battery Recycling

With the increasing popularity of electric bicycles, the proper recycling of e-bike batteries has become paramount. Responsible recycling of these batteries offers a range of environmental and economic benefits.

Environmental Impact

E-bike battery recycling plays a significant role in reducing the environmental impact of electric bicycles. By avoiding improper disposal methods, such as landfilling or incineration, e-bike batteries can prevent the release of hazardous chemicals into the environment. Battery recycling helps to minimize the extraction of raw materials, such as lithium and cobalt, which are finite resources and often sourced from environmentally sensitive areas.

Resource Conservation

E-bike battery recycling allows for the recovery and reuse of valuable materials present in the batteries. This helps in conserving natural resources and reducing the demand for new raw materials. Valuable metals like lithium, cobalt, nickel, and copper can be extracted and used in the production of new batteries or other applications, reducing the need for mining and decreasing the strain on the environment.

Reducing E-waste

The improper disposal of e-bike batteries can contribute to the growing problem of e-waste. E-waste contains toxic substances that can harm human health and the environment if not managed properly. By recycling e-bike batteries, the volume of e-waste can be reduced, and the hazardous components can be safely and responsibly processed. This contributes to a more sustainable and circular approach to waste management.

Current State of E-bike Battery Recycling

While the importance of e-bike battery recycling is evident, there are several challenges and limitations in the current state of the recycling infrastructure.

Lack of Proper Recycling Infrastructure

The recycling infrastructure for e-bike batteries is still in its early stages of development, especially in comparison to other types of batteries. Many regions lack specialized facilities or processes for the efficient and safe recycling of e-bike batteries. This can lead to issues related to inadequate collection and handling of used batteries, resulting in the potential risk of environmental contamination.

Challenges in Recycling E-bike Batteries

E-bike batteries pose unique challenges in the recycling process. The complex composition of batteries, including the presence of hazardous materials, makes their recycling a technically demanding task. Additionally, the small and compact design of e-bike batteries can make it difficult to extract and recover valuable materials efficiently. These challenges highlight the need for dedicated research, innovation, and collaboration within the e-bike industry to develop effective recycling strategies.

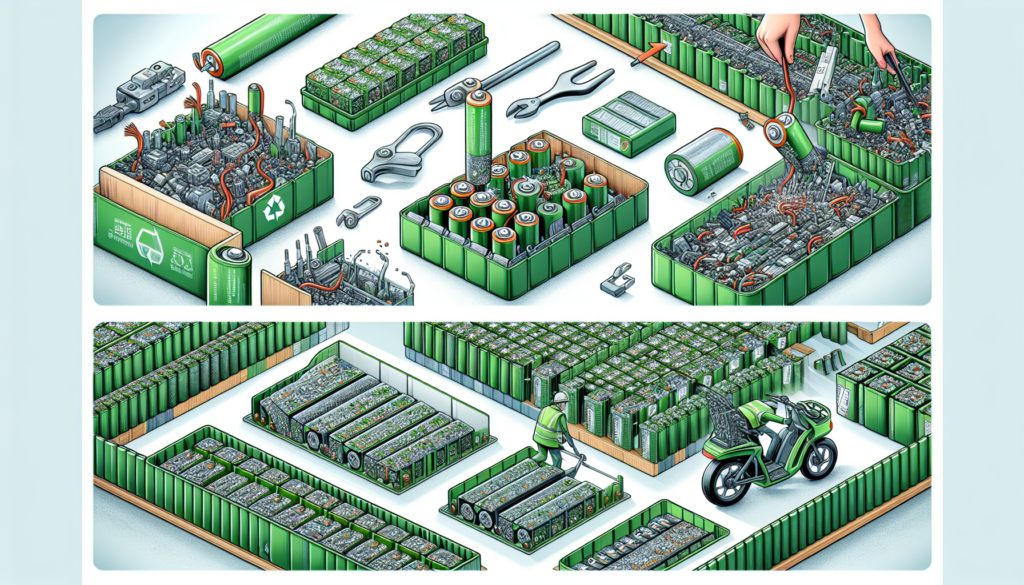

Recycling Methods for E-bike Batteries

To address the challenges of e-bike battery recycling, various methods have been developed and implemented. These methods aim to recover valuable materials, minimize waste, and reduce the environmental impact of battery disposal.

Battery Reuse and Refurbishment

Battery reuse and refurbishment involve testing and sorting used batteries, identifying and replacing defective cells, and reconditioning the remaining cells. This allows for the extension of the battery’s lifespan and maximizes its use before eventual recycling. Reuse and refurbishment are particularly effective when dealing with batteries that still have a significant amount of capacity remaining.

Mechanical Recycling

Mechanical recycling is a process that involves shredding and crushing e-bike batteries to separate the different components. The shredded battery materials are then further processed to recover valuable metals such as lithium, cobalt, and nickel. Mechanical recycling is an efficient method for large-scale battery recycling but may have limitations in terms of material purity and the energy required for the process.

Hydrometallurgical Recycling

Hydrometallurgical recycling involves the use of chemical leaching processes to dissolve and recover metals from e-bike batteries. The leaching solution selectively dissolves the desired metals, allowing for their separation and subsequent recovery. Hydrometallurgical recycling offers the advantage of being able to achieve high metal recovery rates while minimizing energy consumption. However, it can be challenging to manage the chemical solutions and by-products generated during the process.

Pyrometallurgical Recycling

Pyrometallurgical recycling involves the thermal treatment of e-bike batteries, such as high-temperature smelting, to extract metals from the battery components. The high temperatures cause the metals to separate from other battery materials, allowing for their recovery. Pyrometallurgical recycling is effective in achieving high metal recovery rates and can handle a wide range of battery compositions. However, the process is energy-intensive and may result in the emission of pollutants if not properly controlled.

Battery Reuse and Refurbishment

Battery reuse and refurbishment are methods that aim to extend the lifespan of e-bike batteries through careful testing, sorting, and repair.

Testing and Sorting of Used Batteries

Used e-bike batteries undergo thorough testing to assess their capacity, internal resistance, and overall condition. This helps in identifying batteries that are suitable for reuse and those suitable for recycling. Sorting the batteries based on their performance and capacity ensures that only batteries with sufficient remaining capacity are chosen for refurbishment.

Replacement of Defective Cells

During the refurbishment process, any defective cells identified during testing are replaced with new or refurbished cells. This ensures that the battery’s overall performance is optimized and that it can provide a reliable power source for an extended period.

Reconditioning and Recharging

Refurbished batteries go through a reconditioning process, which involves recharging and ensuring that the cells are balanced and functioning properly. This helps in maximizing the battery’s performance and enhancing its lifespan. Once the battery has undergone reconditioning, it is ready to be used in a new e-bike, providing a cost-effective and sustainable solution.

Mechanical Recycling

Mechanical recycling is a widely employed method for e-bike battery recycling, particularly for large-scale operations.

Battery Shredding and Crushing

In the mechanical recycling process, e-bike batteries are shredded and crushed into smaller pieces. This is done to facilitate the subsequent separation of the battery components, including the metal foils, plastic casing, electrolyte, and active materials.

Separation of Battery Components

Once the batteries are shredded, various mechanical and physical techniques are used to separate the different components. This can include sieving, magnetic separation, and air classification. The goal is to isolate the valuable metals and recover them for subsequent processing.

Recovery of Materials

The shredded battery components are further processed to recover valuable materials such as lithium, cobalt, and nickel. This can involve techniques such as hydrometallurgical or pyrometallurgical processes to extract the desired metals. The recovered materials can then be used in the production of new batteries or other applications, minimizing the need for the extraction of virgin resources.

Hydrometallurgical Recycling

Hydrometallurgical recycling is a chemical-based process that enables the selective recovery of metals from e-bike batteries.

Leaching Process

The hydrometallurgical recycling process begins with the leaching of the shredded battery materials. This involves the use of chemical solutions that selectively dissolve the desired metals, while leaving other components intact. The leaching process is carefully controlled to optimize metal recovery and minimize the generation of waste.

Separation of Metal Ions

Once the metals are dissolved in the leaching solution, they can be separated from the other components present in the solution. Various separation techniques, such as precipitation, solvent extraction, and ion exchange, can be employed to achieve the desired metal separation.

Metal Recovery

The separated metal ions are then recovered from the solution through precipitation or electroplating processes. These techniques allow for the conversion of the metal ions back into solid metal form, enabling their reuse or further processing. The recovered metals can be used in the production of new batteries or other applications, closing the recycling loop.

Pyrometallurgical Recycling

Pyrometallurgical recycling involves the thermal treatment of e-bike batteries to separate and recover metals from their components.

Thermal Treatment

In the pyrometallurgical recycling process, e-bike batteries are subjected to high-temperature treatment, typically in a controlled furnace or smelting operation. The heat causes the battery components to undergo various reactions, leading to the separation of the metals from other materials.

Smelting Process

During the smelting process, the high temperatures cause the metals to melt and separate from the other battery components. The molten metals can then be collected and further processed to remove any impurities.

Metal Extraction

After the smelting process, the molten metals are typically refined and purified to achieve the desired metal purity. This can involve techniques such as electrorefining or chemical purification processes. The resulting pure metals can be used in the production of new batteries or other applications.

Efficiency and Limitations of Recycling Methods

The efficiency and limitations of e-bike battery recycling methods are important considerations when evaluating their overall sustainability and effectiveness.

Energy Consumption

The energy consumption associated with different recycling methods varies. Mechanical recycling and hydrometallurgical recycling tend to require less energy compared to pyrometallurgical recycling. However, energy-intensive processes are often necessary for high-temperature operations in pyrometallurgical recycling. Optimizing energy efficiency in recycling processes is critical to minimizing the overall environmental impact.

Purity of Recovered Materials

The purity of the recovered materials is another important factor. Mechanical recycling methods can result in relatively lower purity levels compared to chemical-based processes. However, advancements in separation and refining technologies are continually improving material purity levels across all recycling methods. Higher material purity is crucial for maximizing the value of the recovered metals and ensuring their suitability for reuse in various applications, including battery production.

Economic Viability

The economic viability of different recycling methods is essential for their wider adoption and scalability. Currently, mechanical recycling tends to be more economically viable on a large scale due to its relatively lower equipment and operating costs. Hydrometallurgical and pyrometallurgical recycling methods may require greater investments and technical expertise, making them more suitable for specialized facilities. Continued research and innovation are necessary to optimize the economics of recycling methods and make them accessible to a broader range of stakeholders.

Future Outlook and Research

The future of e-bike battery recycling lies in advancements in recycling technologies and improvements in recycling infrastructure.

Advancements in Battery Recycling Technologies

Ongoing research and development efforts are focused on improving the efficiency and sustainability of e-bike battery recycling methods. This includes exploring innovative separation and refining technologies, as well as investigating more environmentally friendly and energy-efficient processes. Advancements in battery recycling technologies will play a crucial role in maximizing resource recovery and minimizing the environmental impact of e-bike batteries.

Improving Recycling Infrastructure

The development and enhancement of recycling infrastructure are key to ensuring the effective collection and processing of e-bike batteries. Governments, manufacturers, and other stakeholders need to collaborate and invest in the establishment of specialized recycling facilities and the optimization of collection networks. This will support the growth of a comprehensive and robust e-bike battery recycling system that can handle the increasing volume of used batteries.

Research on Sustainable Battery Design

In addition to recycling efforts, research on sustainable battery design is essential for reducing the environmental impact of e-bike batteries throughout their life cycle. This includes exploring alternative materials, improving battery longevity, and enhancing the recyclability of battery components. Sustainable battery design principles, such as eco-design and extended producer responsibility, can help to minimize waste generation and maximize resource conservation.

In conclusion, e-bike battery recycling is an important aspect of promoting environmental sustainability and resource conservation. The proper recycling of e-bike batteries helps to minimize environmental pollution, conserve valuable resources, and reduce the generation of e-waste. While there are challenges and limitations in the current state of e-bike battery recycling, advancements in recycling technologies and infrastructure, along with research on sustainable battery design, offer promising prospects for a more sustainable future. By embracing responsible recycling practices and supporting ongoing research efforts, we can contribute to a cleaner and more sustainable e-bike industry.